HomeCategory

O Ring Manufacturers

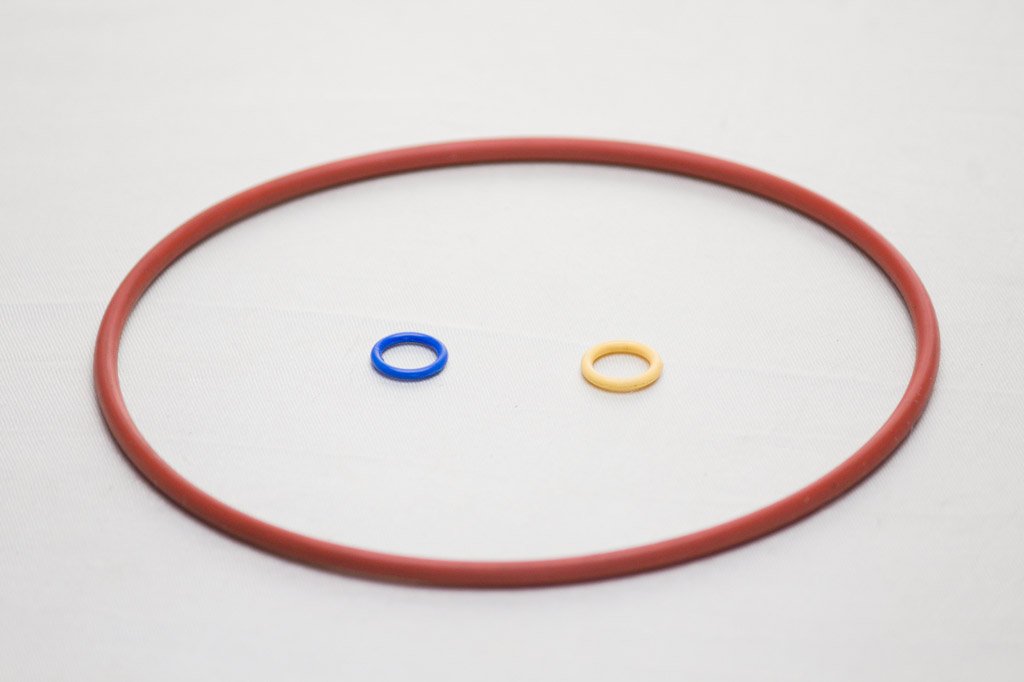

Get Premium Sealing Solutions with GB Rubber Products - India's Finest O ring manufacturers.

As one of the finest O ring manufacturers in India, we specialise in providing top-notch O ring solutions tailored to your specific needs. Our expertise in custom rubber and rubber-to-metal bonded parts ensures you receive the highest quality products, designed with your operational requirements in mind. Our team of experts ensures that every product meets the highest standards of quality and performance. As dedicated O ring manufacturers, we pride ourselves on our prompt service and personalized assistance, guaranteeing customer satisfaction every step of the way. Reach out to us today to explore our customized sealing solutions and experience the difference.

FAQs

The meticulous process of crafting o rings involves precision and excellence. O ring manufacturers begin the process by carefully selecting materials like rubber or elastomer. Through molding or extrusion, the material is given a distinctive circular shape. Three molding processes produce O rings - compression, injection, and transfer. Later, the material is introduced to the curing process, which enhances the durability and uniformity of the o rings. The final stage of the o ring manufacturing involves the stringent quality check and testing of the o rings, which comes out as the final product. This systematic approach guarantees the production of premium quality O rings, ensuring robust sealing solutions.

O-rings serve as a critical sealing partner by creating a secure, tight, and resistant barrier between two components. The purpose of o-rings extends beyond simple sealing as they are reliable and efficient, preventing leakage of liquid and gas and acting as a shock absorber, dampening vibrations and minimizing mechanical tensions. Whether in automotive, aerospace, medical, or manufacturing, O ring manufacturers play a crucial role in ensuring operational integrity. By producing versatile O rings, they act as barriers against contaminants, dust, or moisture, effectively preventing leakage and maintaining product reliability. The multifaceted role of O rings makes it an indispensable component in various industries, contributing to the overall functionality of mechanical systems

Crafting O rings involves a careful selection of materials. O ring manufacturers employ a variety of materials tailored according to the application's requirements. The common materials used to produce O rings include Nitrite, which offers versatility, Viton for high-temperature resistance and chemical environment, and Silicone for flexibility. Other materials include EPDM, Neoprene, or PTFE, each selected for the most suitable properties for the application. Therefore, the selection of materials by the manufacturers ensures that the O rings meet the industrial demand, performance, and durability across various industries.

O rings perform by creating a solid seal between two between two surfaces. The circular design of these components enables them to effectively prevent any leakage of liquid or gases by ensuring air-tight solutions. When an O ring is compressed between surfaces, it exerts a radial force, which helps to create a barrier against any leaks and contaminations. The sealing mechanism of these components is used across various industries, such as automotive, aerospace, medical, manufacturing, and agriculture. O ring manufacturers create these components with great attention to detail to promise resilience, effectiveness, and durability across various applications.